-

-

Products

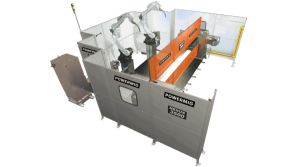

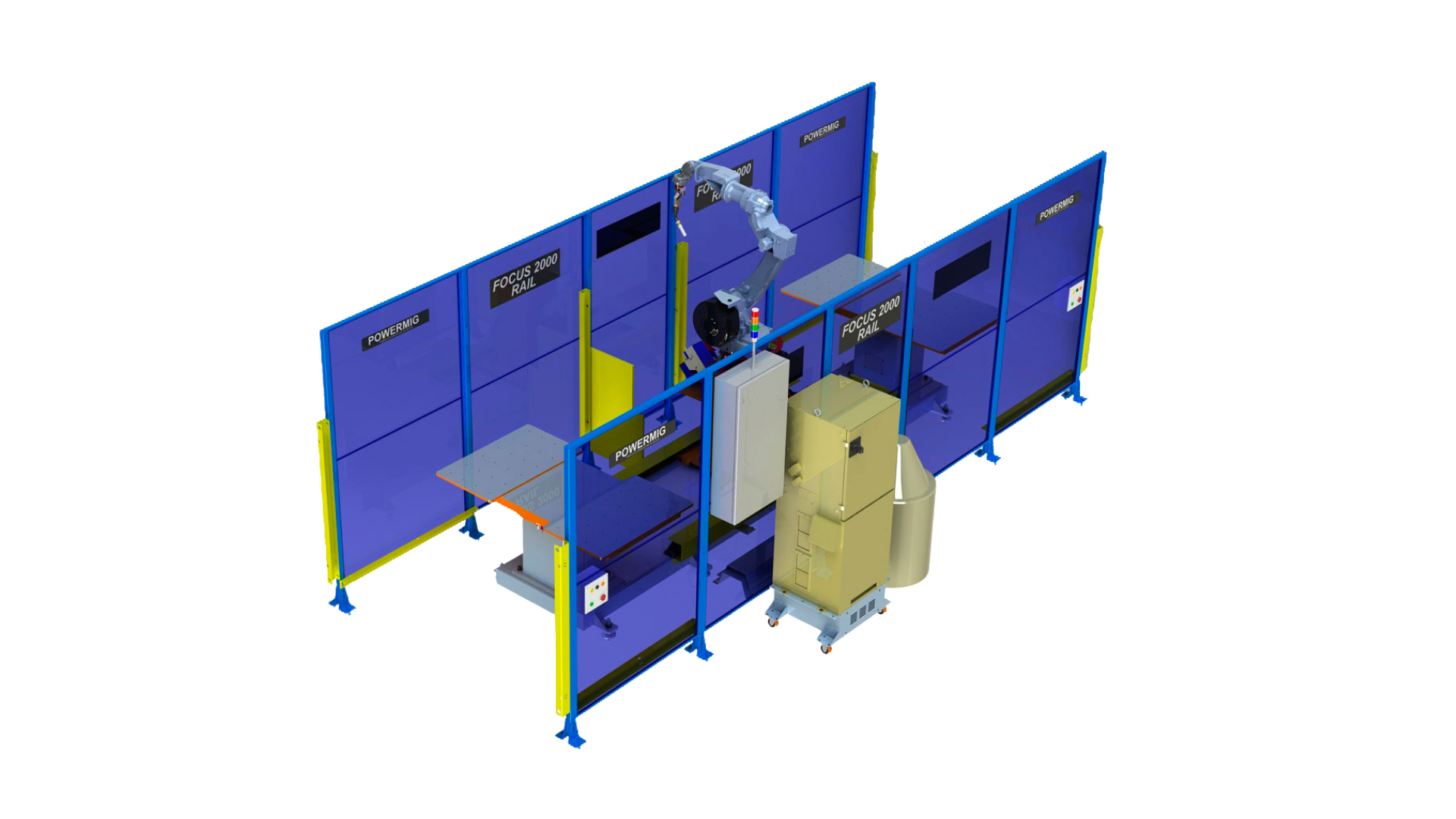

Robotized Cells

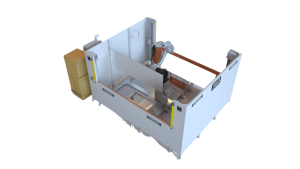

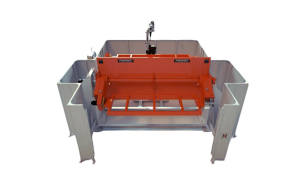

Fixed Table

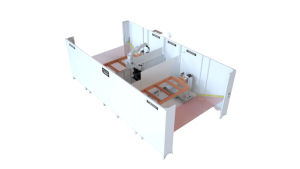

Rotatory Table

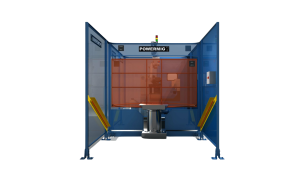

Vertical Positioner

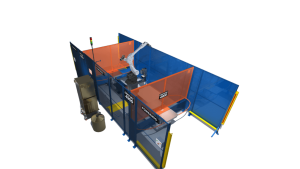

Horizontal Positioner

Orbital Positioner

Special Projects

Robozited Welding

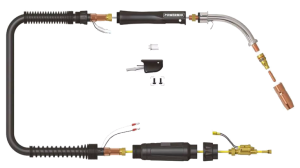

Robotic Welding Torches

PANASONIC Robot

Positioners

Softwares

Power Cleaner

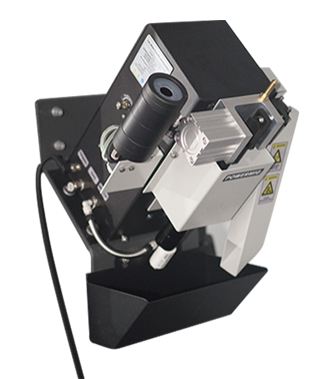

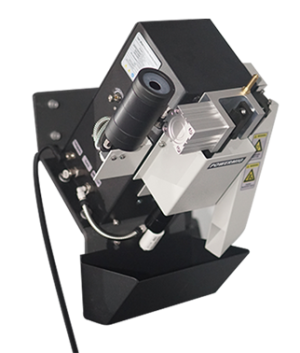

Intelligent Laser

Soldering Products

Manual Torches

Welding Machines

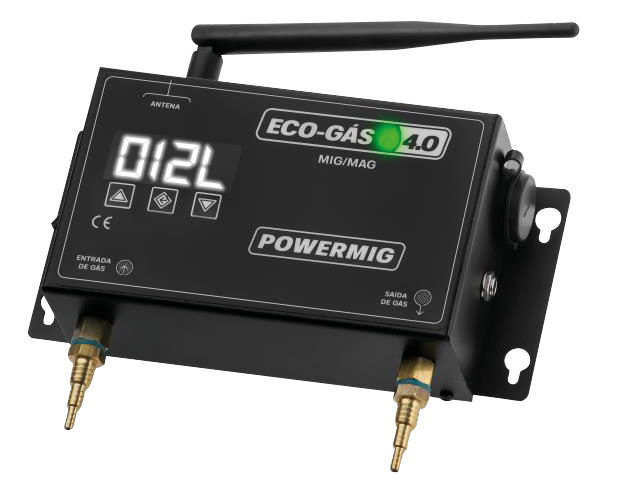

Eco-Gás 4.0

Spatter Off

Power Chiller

Ceramic Protector

Safety Door

Solid Welding Wires

Máquinas de Solda Manuais

Power Liner

Power Shield

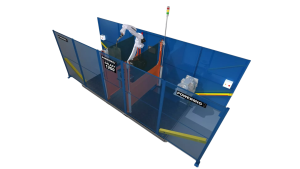

Soldagem Colaborativa COBOTS

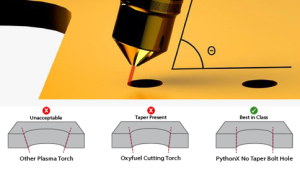

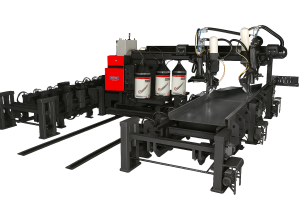

Soluções de Corte PythonX

Hard Automation

Sistemas de Soldagem Automáticos

Plus System

Lincoln Process for Shared Unit

- Services

-

About

- FAQ

-

Contact

English